| Art./Item | Pcs |

|---|---|

| 27943 | 1 |

An anti-fall device on a 12 mm diameter and 15 m long Kernmantle rope equipped with a strong steel connector and self-locking mechanism. This fall arrest rope is equipped with an energy absorber with webbing and a containment casing to reduce the force of impact in the event of a fall.

The Easy rope fall arrest device, certified for horizontal use on sharp edges, is particularly suitable for work on pitches and pylons, ensuring the operator can move freely and maintain balance in unstable conditions.

TECHNICAL SPECIFICATIONS

- 12 mm diameter and 15 m long Kernmantle rope

- Self-locking steel mechanism

- Connector

- Energy absorber with 32 mm webbing and PE casing

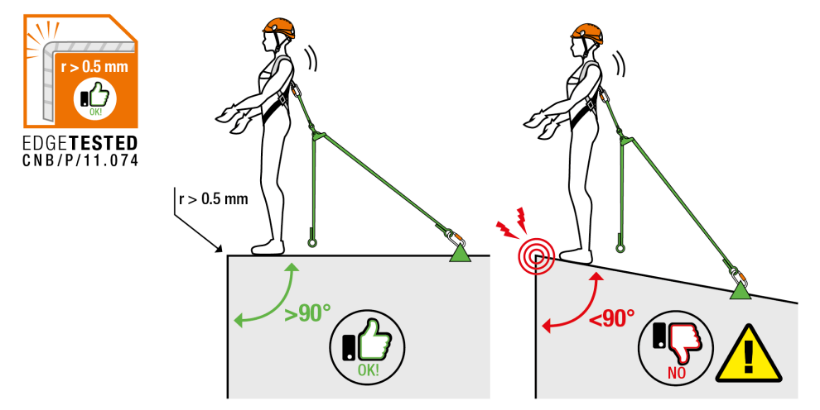

- Certified for horizontal use on sharp edges

- Standard EN 353-2

MATERIAL

- Rope: polyester

- Connector: steel

- Webbing: polyamide

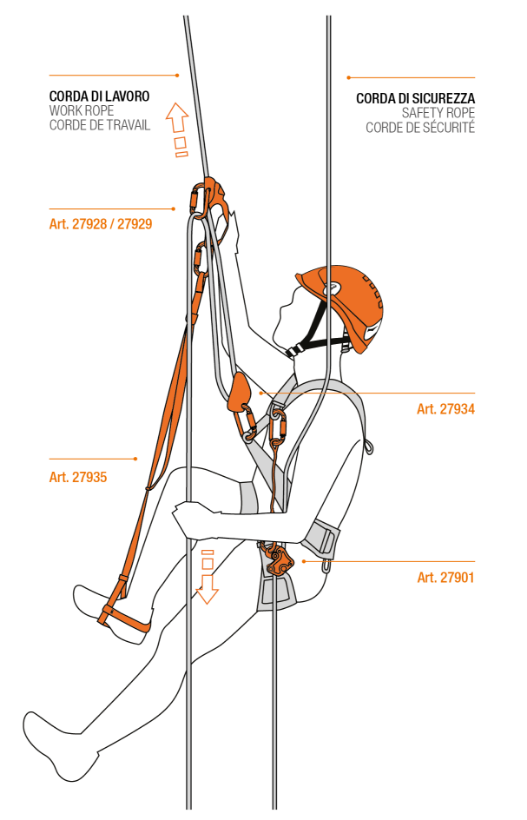

Use ascent on a fixed rope

Rope fall protection systems

Resistance on sharp edge

Maintenance and storage of PPE

PPE periodic checks and inspections

Use: access to workplace from below - ascent on a fixed rope (art. 27928/27929)

1. Both the ascent rope and the fall arrester rope must be previously secured to the anchor points at height

2. Connect the fall arrester device to the breast or back harness ring

3. Connect the handle with the ascent bracket and the descender to the ascent/descent rope. In this phase the descender acts as a blocker during the repositioning of the handle

4. To descend, simply release the handle with the ascent bracket connected and activate the descender

The rope fall protection equipment comply with EN 353-2 standard requirements. They connect directly to the harness by means of a connector. They are fitted with a slide system that blocks in the event of a fall, allowing the operator to work in safe conditions whilst maximum freedom of movement. The rope fall protection devices are particularly useful for work on pitches, trellis, scaffolding and for suspension work. The device can be held by the operator to ease the sliding motion and help him keep his balance in situations of instability.

The rope fall protection devices can be openable or closed.

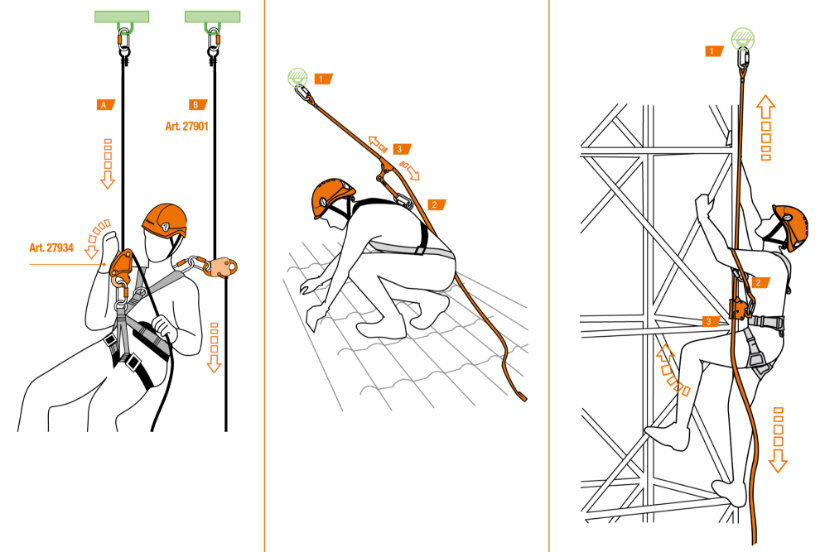

USE ON ROPE - ACCESS FROM ABOVE

Very often, accessing from above at the workplace is faster and safer. Prepare two anchor points, one for the semistatic work rope hooking (A) and the other for the safety rope (B). Pass the work rope in the descender-belay device connected to the front anchorage point of the harness. On the safety rope (B) slides the fall arrester device connected to the dorsal anchorage point of the harness. The descent must be slow in order not to overheat the rope that crosses the descender.

USE ON PITCH

1. Connect the rope fall protection equipment to the anchor point

2. Connect the connector to the breast or back harness ring

3. Progress in total freedom both up and down, the device follows the operator’s movements, ready to interven. If used on particularly inclined pitches, the rope can be used as a support to help the operator during the ascent.

USE ON METALLIC STRUCTURE

1. Connect the rope fall protection equipment to the anchor point

2. Connect the rope fall protection device connector to the breast or back harness ring

3. Progress in total freedom both up and down, the device follows the operator’s movements, ready to interven

Static ropes and lanyards made of polyester/polyamide with wear-resistant internal core and external covering are certified for horizontal use on a sharp edge.

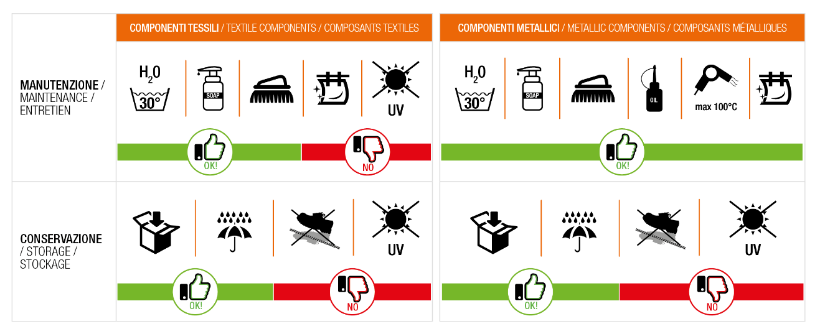

Correct and regular maintenance helps prevent premature ageing of PPE. For this reason, users are recommended to carefully respect all indications found in the user and maintenance manual that accompanies each PPE and to follow the simple storage and preservation rules:

- Keep away from sunlight and UV rays as these are the primary cause of ageing of PPE textile fibers

- Keep PPE away from direct heat sources as the synthetic textile fibers used to make harnesses, lanyards, and energy absorption systems have a very low melting temperature

- PPE must be stored in cool and dry areas, as humidity generates mold harmful to textile fibers and corrosive on metal parts

- A periodic cleaning operation is essential to ensure a good durability of the PPE

- A washing with lukewarm water eliminates surface dirt and that present inside the textile fibers

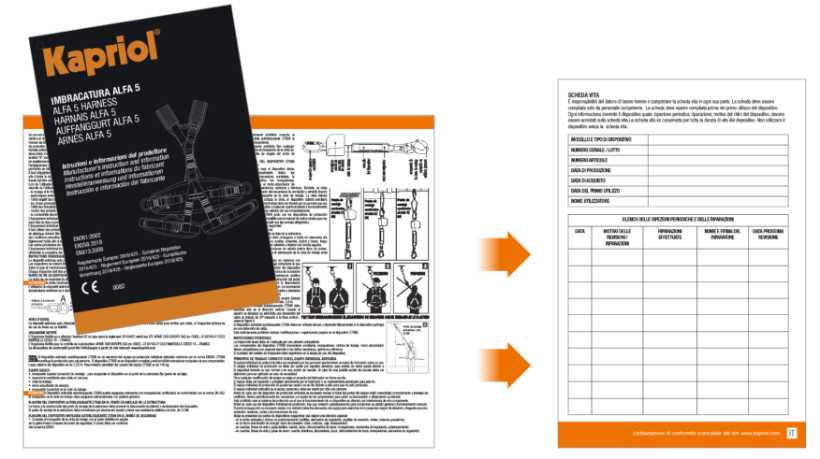

The current legislation requires that each equipment must be subjected to periodic inspections:

- Before, during and after use, the user must check the PPE conditions and integrity through a visual inspection after each use

- At least every 12 months, PPE must be subjected to mandatory periodic checks and inspections by competent personnel authorized by the manufacturing company

Each PPE is accompanied by a manual and identity card that must be kept for the entire use duration of the product and filled in with the periodic inspections data.

Recommended use

Restraint (on fixed surface)

Positioning (on upright)

Inclined surface

Confined spaces