| Art./Item | Pcs |

|---|---|

| 27998 | 1 |

Temporary lifeline with 20 m polyester strap with two reinforced connection loops and tensioner ratchet. The temporary horizontal lifeline can be used by 3 operators at the same time and allows workers to be protected from possible falls from height, thus minimising the risks for workers carrying out work at height.

The Kapriol lifeline is supplied with a backpack for transport and storage.

TECHNICAL SPECIFICATIONS

- Strap length 20 m

- Two reinforced connecting loops

- Ratchet tensioner

- Backpack for transport and storage

- EN 795B standard

MATERIAL

- Strap: polyester

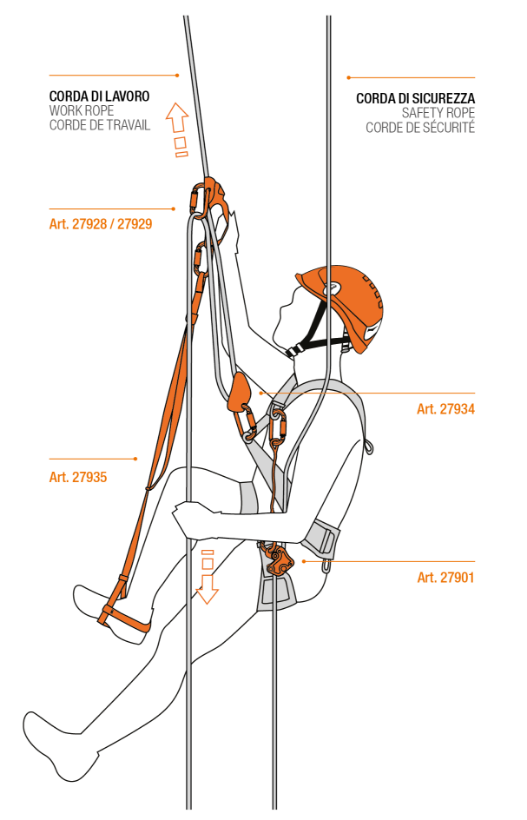

Use ascent on a fixed rope

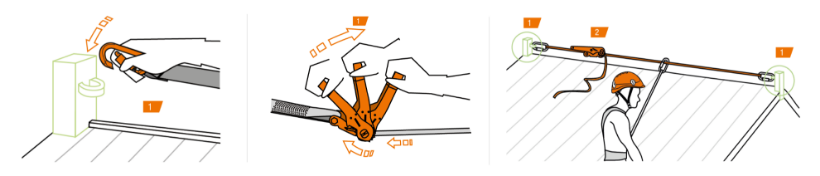

Anchorage lifeline on pitch

Maintenance and storage of PPE

PPE periodic checks and inspections

Use: access to workplace from below - ascent on a fixed rope (art. 27928/27929)

1. Both the ascent rope and the fall arrester rope must be previously secured to the anchor points at height

2. Connect the fall arrester device to the breast or back harness ring

3. Connect the handle with the ascent bracket and the descender to the ascent/descent rope. In this phase the descender acts as a blocker during the repositioning of the handle

4. To descend, simply release the handle with the ascent bracket connected and activate the descender

Hooking to the structure

1. Connect the rings present at the ends of the lifeline to previously installed anchor points, using connectors with high breaking load.

Tensionamento linea vita

1. After manually shortening the length of the lifeline to size, proceed with tensioning by operating the ratchet back and forth.

2. Place the ratchet in the rest position and cover it with the appropriate protective case, in order to avoid accidental operations or possible damages.

Use of lifeline

1. Connect the end rings of the lifeline to the existing anchors previously identified, for this operation it may be necessary to use other fall arrest systems connected to individual anchor points. Check the Operational Safety Plan.

2. Properly tension the lifeline through the appropriate ratchet present at one end of the lifeline.

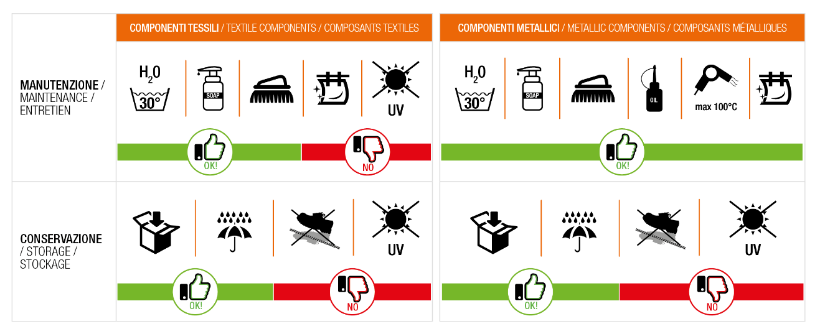

Correct and regular maintenance helps prevent premature ageing of PPE. For this reason, users are recommended to carefully respect all indications found in the user and maintenance manual that accompanies each PPE and to follow the simple storage and preservation rules:

- Keep away from sunlight and UV rays as these are the primary cause of ageing of PPE textile fibers

- Keep PPE away from direct heat sources as the synthetic textile fibers used to make harnesses, lanyards, and energy absorption systems have a very low melting temperature

- PPE must be stored in cool and dry areas, as humidity generates mold harmful to textile fibers and corrosive on metal parts

- A periodic cleaning operation is essential to ensure a good durability of the PPE

- A washing with lukewarm water eliminates surface dirt and that present inside the textile fibers

The current legislation requires that each equipment must be subjected to periodic inspections:

- Before, during and after use, the user must check the PPE conditions and integrity through a visual inspection after each use

- At least every 12 months, PPE must be subjected to mandatory periodic checks and inspections by competent personnel authorized by the manufacturing company

Each PPE is accompanied by a manual and identity card that must be kept for the entire use duration of the product and filled in with the periodic inspections data.

Recommended use

Inclined surface

Scaffolding