| Art./Item |  Foro dischi (mm.) Foro dischi (mm.) | Ø (mm.) | Sett. Q.tà |

|---|---|---|---|

| 54645 | 22,2 | 100 | c.c. |

| 54646 | 22,2 | 125 | c.c. |

| 54647 | 22,2 | 180 | c.c. |

MATERIAL TYPES

Brick ![]() 🟠🟠🟠

🟠🟠🟠

Concrete 🟠🟠🟠

Abrasives/Refractory ![]() 🟠

🟠

Granite/Stone 🟠🟠🟠

CUTTING INFORMATION

![]() Dry cut

Dry cut

![]() Humid cut

Humid cut

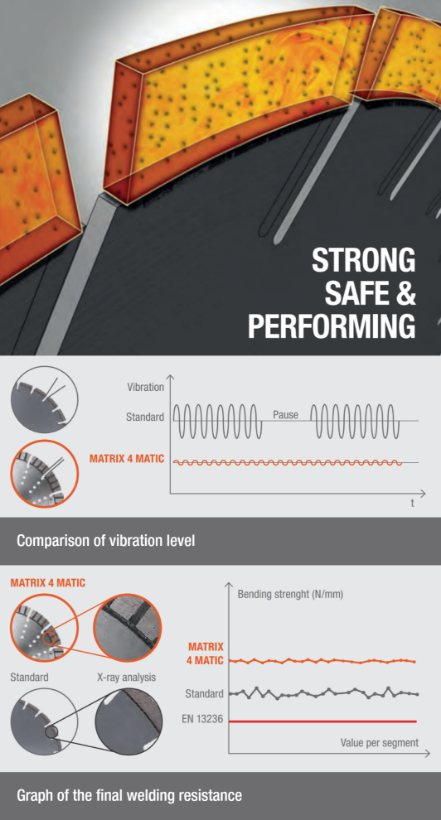

Technology

Forged Germantechnology

The revolutionary forging technology allows the use of an exclusive mix, up to now never used, of binders and diamonds that give the blade the maximum cutting versatility on all types of materials. These used binders have the peculiarity of being able to withstand heat considerably, actually they improve performance when they are maximally stressed.

Pulse Welding

Pulse welding makes diamond blades safe and reliable even under thermal stress.

Performance

Platinum

Innovative product with aa special design that responds to the most advanced technology and provides additional benefits (low noise, cooling, etc.).

High speed

Blade manufactured with special technologies that make it particularlyfast.

Long life

Grazie alle speciali tecnologie con cui è stato costruito, il disco garantisce una lunga durata di utilizzo.

Wet and dry cutting

Forged Advantages

Reduced vibration and increased operator comfort, thanks to the trapezoidal diamond segment that makes the space between the diamond segments parallel and not angular.

The 100% density and compactness of the forged diamond segment and the absence of porosity within it guarantee laser welding that reduces the possibility of breakage or detachment of the segments from the disc core by 50%.