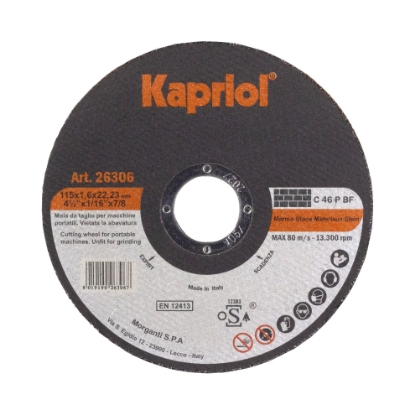

| Art./Item |  Foro dischi (mm.) Foro dischi (mm.) | Ø (mm.) |  thickness thickness | Sett.Altezza | Sett. Q.tà |

|---|---|---|---|---|---|

| 54560 | 22,2 | 115 | 1,9 | 3 | 14 |

| 54563 | 22,2 | 230 | 2,5 | 3 | 14 |

Master Finish Pro cutting disc made with Vacuum technology that allows high diamond exposure and improves cutting efficiency, cooling and durability. This diamond cutting disc is particularly suitable for dry or wet cutting of marble and fibreglass, guaranteeing a clean, clean cut even for very tough materials.

The Master Finish Pro cutting disc for portable machines is available with different diameters from 115 mm up to 230 mm and a photo of 22.2 mm.

MATERIAL TYPE

- Marble 🟠🟠🟠

- Fibreglass 🟠🟠🟠

QUALITY STANDARDS

- Platinum quality

CUTTING INSTRUCTIONS

- Dry cutting

- Wet cutting

Technology

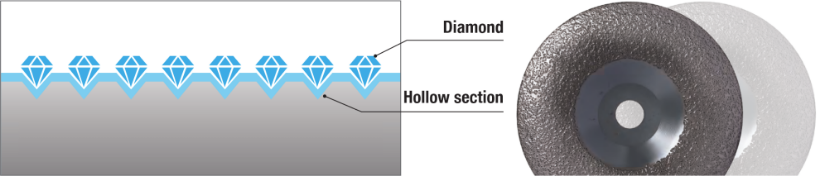

Vcuum Technology

Technology developed on the chemical bond between diamond and matrix that permanently solders the diamond to the substrate allowing a high exposure. With Vacuum technology, the diamond exposure is significantly higher than the sintering and galvanizing process, improving cutting efficiency, cooling and life.

Performance

Long life

Grazie alle speciali tecnologie con cui è stato costruito, il disco garantisce una lunga durata di utilizzo.

High speed

Blade manufactured with special technologies that make it particularlyfast.

Clean cut

Clean and neat cut on tough and durable materials.

Wet and dry cutting

OSA - EN13236 certified quality

Vacuum Advantages

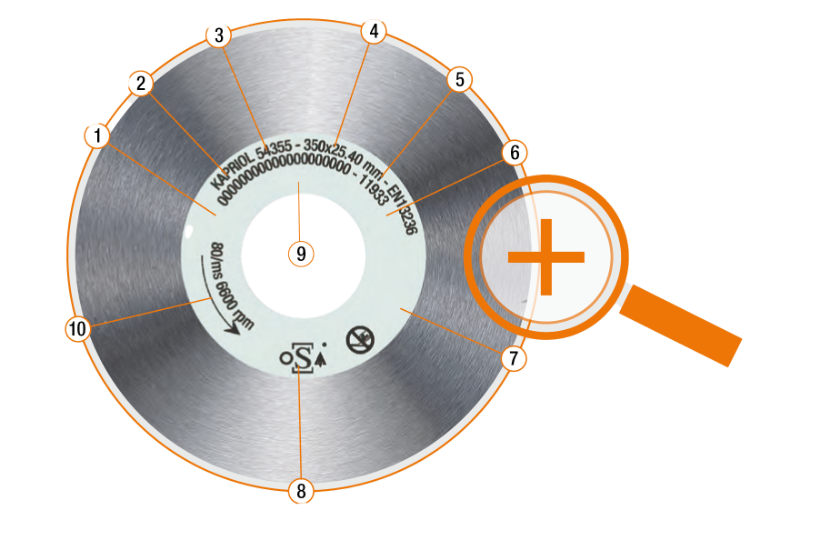

Kapriol Power Tools has OSA certification (Organisation for the Safety of Abrasives). OSA marking certifies that the product complies with manufacturing, quality and safety regulations according to EN 13236 and the safety standards in force. This regulation contains all prescriptions and/or safety measures to be taken in order to prevent or reduce dangers deriving from design and use of abrasive/diamond tools.

1. Name of the manufacturer

2. Traceability code

3. Manufacturer identification number

4. Maximum working speed in m/s

5. Maximum rotation speed (rpm

6. Declaration of conformity

7. Restrictions of use

8. OSA Marking

9. Dimensions

10. Direction of rotation

The hollow section created with Vacuum technology eliminates heat damage to the diamond, maintains the chemical structure and physical performance, and prevents damage.