| Art./Item |  Foro dischi (mm.) Foro dischi (mm.) | Ø (mm.) |  thickness thickness | Sett.Altezza | Sett. Q.tà |

|---|---|---|---|---|---|

| 54304 | 22,2 | 230 | 2,80 | 17 | 15 |

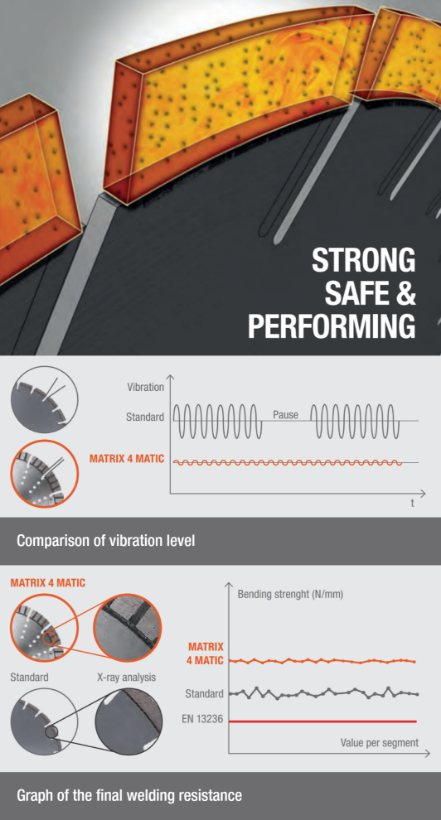

Diamond cutting disc made using Forged technology, which through the use of an exclusive mix of binders and diamonds, gives the disc maximum cutting versatility on all types of materials. This diamond blade is suitable for cutting tough materials such as reinforced concrete, lateritic, stone, iron and cast iron.

The Matrix 4Matic Evolution cutting disc guarantees reduced vibration and increased operator comfort, as well as a 50% reduction in the possibility of segment breakage or detachment from the disc core.

OSA certified in accordance with EN 13236, Kapriol cutting discs guarantee high performance and long life.

MATERIAL TYPE

- Brick 🟠🟠🟠

- Cement 🟠🟠🟠

- Reinforced concrete 🟠🟠🟠

- Abrasives/Refractories 🟠🟠🟠

- Iron/Ghisa 🟠🟠🟠

- Granite/Stone 🟠🟠🟠

- Asphalt 🟠🟠

QUALITY STANDARDS

- Platinum quality

CUTTING INSTRUCTIONS

- Dry cutting

- Wet cutting

Technology

Forged Germantechnology

The revolutionary forging technology allows the use of an exclusive mix, up to now never used, of binders and diamonds that give the blade the maximum cutting versatility on all types of materials. These used binders have the peculiarity of being able to withstand heat considerably, actually they improve performance when they are maximally stressed.

Laser

Laser welding ensures maximum precision and strength for diamond blades.

Performance

Platinum

Innovative product with aa special design that responds to the most advanced technology and provides additional benefits (low noise, cooling, etc.).

Long life

Grazie alle speciali tecnologie con cui è stato costruito, il disco garantisce una lunga durata di utilizzo.

High speed

Blade manufactured with special technologies that make it particularlyfast.

Height 17 mm

Diamond segment with increased height. Ensures fong life of the blade.

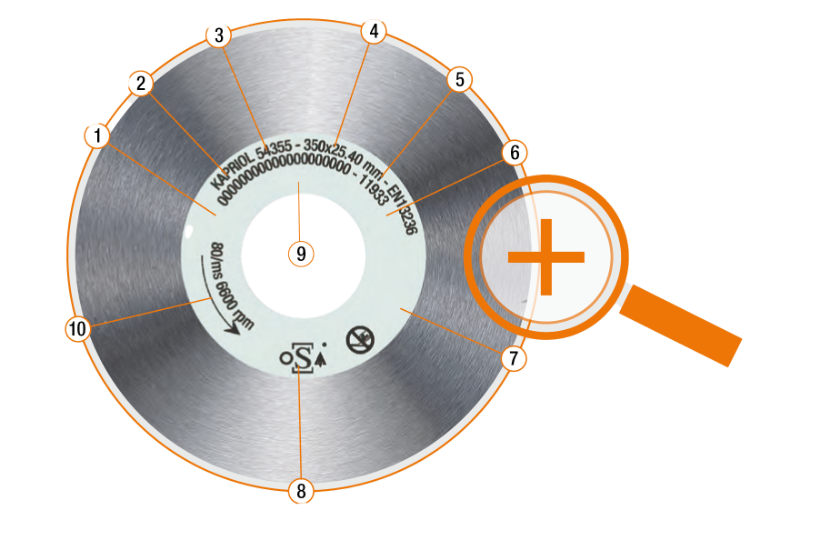

OSA - EN13236 certified quality

Forged Advantages

Kapriol Power Tools has OSA certification (Organisation for the Safety of Abrasives). OSA marking certifies that the product complies with manufacturing, quality and safety regulations according to EN 13236 and the safety standards in force. This regulation contains all prescriptions and/or safety measures to be taken in order to prevent or reduce dangers deriving from design and use of abrasive/diamond tools.

1. Name of the manufacturer

2. Traceability code

3. Manufacturer identification number

4. Maximum working speed in m/s

5. Maximum rotation speed (rpm

6. Declaration of conformity

7. Restrictions of use

8. OSA Marking

9. Dimensions

10. Direction of rotation

Reduced vibration and increased operator comfort, thanks to the trapezoidal diamond segment that makes the space between the diamond segments parallel and not angular.

The 100% density and compactness of the forged diamond segment and the absence of porosity within it guarantee laser welding that reduces the possibility of breakage or detachment of the segments from the disc core by 50%.