| Art./Item |  Foro dischi (mm.) Foro dischi (mm.) | Ø (mm.) |  thickness thickness | Sett.Altezza | Sett. Q.tà |

|---|---|---|---|---|---|

| 54335 | 22,2 | 115 | 2,1 | 10 | c.c. |

| 54337 | 22,2 | 125 | 2,1 | 10 | c.c. |

| 54336 | 22,2 | 230 | 2,5 | 10 | c.c. |

The Zenith 3D F-TG diamond grinding disc in platinum quality is suitable for cutting brick, concrete, reinforced concrete, abrasive/refractory materials, granite and stone. The high speed technology offers high speed and a clean cut even on tough materials.

This diamond blade is manufactured using modern Zenith 3D technology based on the geometric arrangement of diamond grains, which can increase the lifetime and performance of the diamond blade by 30 to 70%.

Suitable for both dry and wet cutting, the Zenith 3D F-TG diamond blade guarantees a long service life, making it a reliable tool for professionals.

MATERIAL TYPE

- Brick 🟠🟠🟠

- Cement 🟠🟠🟠

- Reinforced concrete 🟠🟠🟠

- Abrasives/Refractories 🟠🟠

- Granite/Stone 🟠🟠🟠

QUALITY STANDARDS

- Platinum quality

CUTTING INSTRUCTIONS

- Dry cutting

- Wet cutting

Technology

Zenith 3D Technology

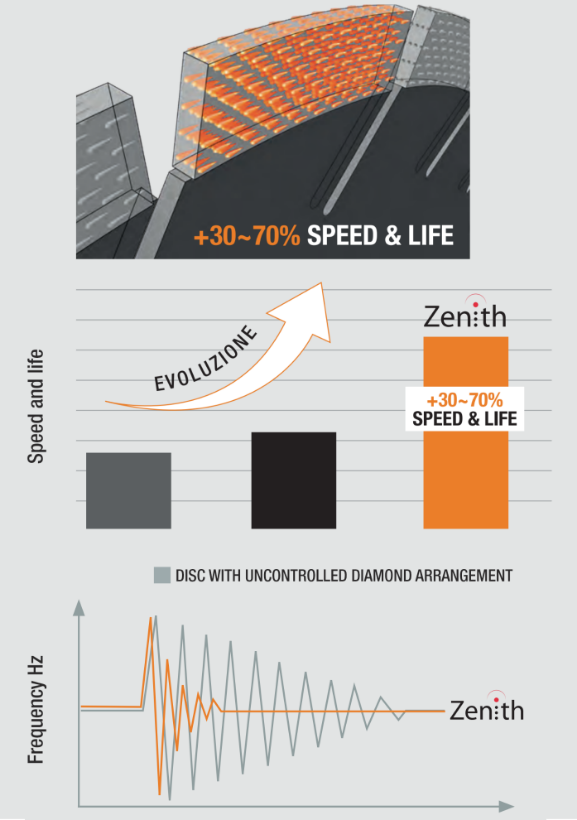

Zenith 3D technology relies on a particular geometric configuration of the diamond grains that improves the durability and performance of the diamond tool between 30% and 70%.

Performance

Platinum

Innovative product with aa special design that responds to the most advanced technology and provides additional benefits (low noise, cooling, etc.).

Long life

Grazie alle speciali tecnologie con cui è stato costruito, il disco garantisce una lunga durata di utilizzo.

High speed

Blade manufactured with special technologies that make it particularlyfast.

Clean cut

Clean and neat cut on tough and durable materials.

Wet and dry cutting

OSA - EN13236 certified quality

Zenith Advantages

Kapriol Power Tools has OSA certification (Organisation for the Safety of Abrasives). OSA marking certifies that the product complies with manufacturing, quality and safety regulations according to EN 13236 and the safety standards in force. This regulation contains all prescriptions and/or safety measures to be taken in order to prevent or reduce dangers deriving from design and use of abrasive/diamond tools.

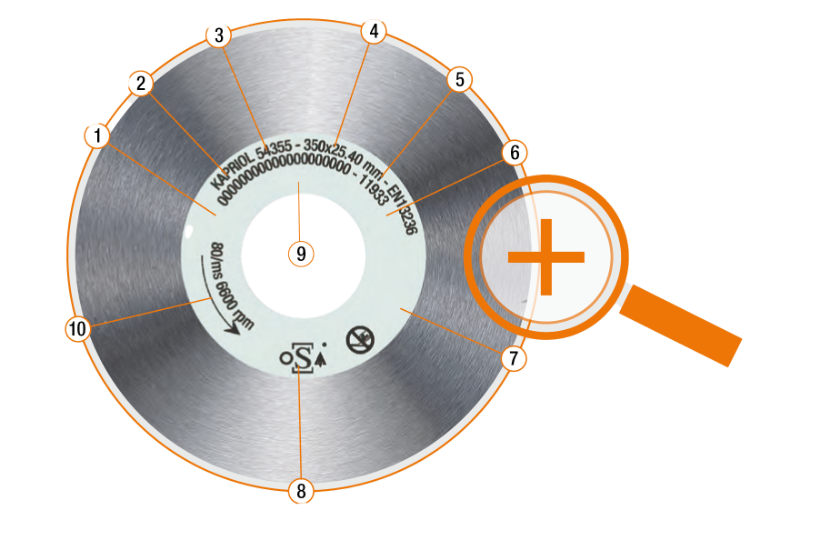

1. Name of the manufacturer

2. Traceability code

3. Manufacturer identification number

4. Maximum working speed in m/s

5. Maximum rotation speed (rpm

6. Declaration of conformity

7. Restrictions of use

8. OSA Marking

9. Dimensions

10. Direction of rotation

In conventional tool manufacture, cutting speed and tool life are two inversely proportional factors. All manufacturers in the past have aimed to produce diamond tools that combine these two parameters.

Zenith 3D Evolution has surpassed the limit imposed by old technologies by achieving exceptional speed and tool life performance, the result of huge investment in research and in advanced, automated production systems, guaranteeing consistent production standards.

The uniform consumption of the diamond disc allows the tool to be constantly revived, maintaining maximum stability and almost totally eliminating overload and vibration to the operator, especially in manual applications.