| Art./Item | Comp. |

|---|---|

| 99128 | 27996 n.1 |

Complete fall arrest kit for the total safety of operators working on metal structures, lifelines or cranes.

The fall arrest kit includes all the fall protection PPE required to allow operators to move around safely, using fall arrest webbing with two connectors that allows the two lanyards to move forward by alternately anchoring the two lanyards, guaranteeing total safety for the user by preventing possible accidental falls.

This Kapriol fall arrest kit is the ideal solution for crane fitters.

TECHNICAL SPECIFICATIONS

- Airkap protective helmet with ABS shell and chin strap with emergency release

- Alfa 5 harness with dorsal fall arrester ring (A), sternal fall arrester ring (A), ventral ring and two lateral positioning rings, padded and adjustable leg loops, adjustable back braces and elastics, and ergonomic backrest

- Two-connector steel elastic fall-prevention lanyard with safety lever and energy absorber (1.5 m long), for attachment to the structure

- Adjustable positioning rope lanyard with locking system, aluminium alloy adjuster and two steel connectors

- PVC backpack for carrying PPE, UV and impact resistant

Maintenance and storage of PPE

PPE periodic checks and inspections

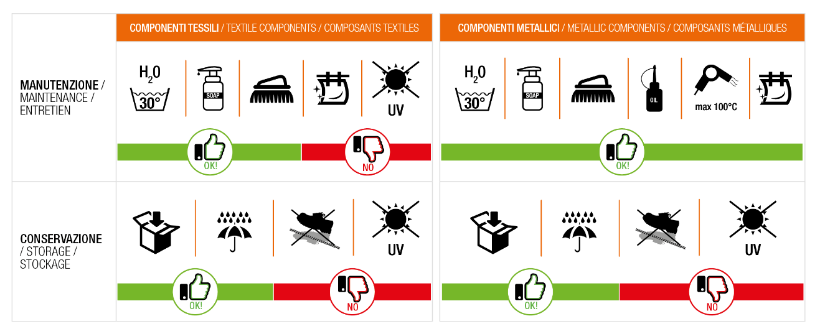

Correct and regular maintenance helps prevent premature ageing of PPE. For this reason, users are recommended to carefully respect all indications found in the user and maintenance manual that accompanies each PPE and to follow the simple storage and preservation rules:

- Keep away from sunlight and UV rays as these are the primary cause of ageing of PPE textile fibers

- Keep PPE away from direct heat sources as the synthetic textile fibers used to make harnesses, lanyards, and energy absorption systems have a very low melting temperature

- PPE must be stored in cool and dry areas, as humidity generates mold harmful to textile fibers and corrosive on metal parts

- A periodic cleaning operation is essential to ensure a good durability of the PPE

- A washing with lukewarm water eliminates surface dirt and that present inside the textile fibers

The current legislation requires that each equipment must be subjected to periodic inspections:

- Before, during and after use, the user must check the PPE conditions and integrity through a visual inspection after each use

- At least every 12 months, PPE must be subjected to mandatory periodic checks and inspections by competent personnel authorized by the manufacturing company

Each PPE is accompanied by a manual and identity card that must be kept for the entire use duration of the product and filled in with the periodic inspections data.

Recommended use